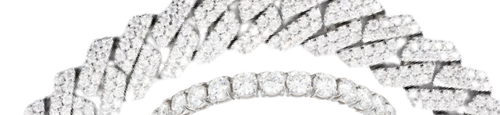

Cuban link chains, with their timeless appeal and dash of boldness, are an evergreen favorite in the realm of jewelry. The transformation of raw metal into an exquisite piece of jewelry exuding style and sophistication is indeed a fascinating journey. In this article, we will delve into the meticulous craftsmanship behind the creation of these iconic chains.

Tools and Materials:

Before exploring the crafting process, it's crucial to understand the materials and tools that play a significant role. Cuban link chains are primarily composed of gold or silver. The individual links are made from a wire formed from the metal. Various tools, including rolling mills, drawplates, mandrels, pliers, and torches, are instrumental in shaping and assembling the chain.

The Step-by-Step Process:

Step 1: Metal Preparation

The creation process commences with the preparation of the metal. The metal is first melted and poured into molds to form ingots. These ingots are subsequently passed through a rolling mill multiple times to be flattened into a sheet. This metal sheet is further passed through a drawplate to form a long, thin wire.

Step 2: Forming the Links

Once the wire is ready, it is wound around a mandrel to create a coil. The coil is then cut vertically to produce individual links. Each link is essentially a small piece of wire bent into an oval shape.

Step 3: Assembling the Chain

The individual links are assembled by connecting them together. This is done by opening one link, passing another through it, and then closing it. This procedure is repeated until the chain achieves the required length.

Step 4: Soldering

To ensure the links are secure and the chain is sturdy, the links are soldered together. This involves applying a small amount of solder to the joint of each link and then heating it with a torch. The solder melts, causing the links to fuse together.

Step 5: Shaping the Links

Post soldering, the chain is shaped to give the links the distinctive Cuban link appearance. The chain is passed through a rolling mill, applying pressure to flatten the links. This process creates the distinctive close-set, rope-like pattern of the Cuban link chain.

Step 6: Polishing and Finishing

The process concludes with polishing and finishing. The chain is cleaned to get rid of any soldering residue, and then it is polished to bestow it a glossy finish and a smooth surface. Additionally, rhodium plating might be used to enhance durability and alter the color tone.

Quality and Authenticity:

Crafting a Cuban link chain demands precision and a keen eye for detail. Authentic Cuban link chains, made from high-quality metals, are renowned for their durability and classic design. When purchasing a Cuban link chain, it's crucial to seek certificates and markings that affirm the metal's purity.

Conclusion:

The craft of making Cuban link chains marries traditional methods with precise artistry. Each step, from the initial cleaning of the metal to the final polishing, plays a pivotal role in defining the chain's unique design. Understanding the time and effort invested in crafting Cuban link chains enhances the appreciation for their timeless beauty. Renowned for their elegance and longevity, Cuban link chains, whether worn as a standout piece or a subtle accent, are a testament to the art of jewelry making.