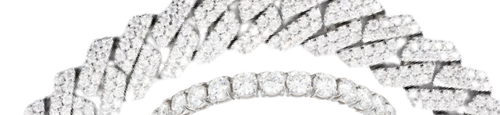

Creating a custom pendant allows you to wear a piece of jewelry that is uniquely yours. Whether it's a representation of personal memories, beliefs, or simply an embodiment of your style, a custom pendant can be a beautiful expression of individuality. This guide will take you step-by-step through the process of designing and manufacturing your own pendant, ensuring you end up with a treasured piece that stands out in a crowd.

1. Find out the Design for the Pendant

Designing the pendant is the first and perhaps most critical step in the custom pendant-making process. The design you choose will dictate the overall look, feel, and significance of the finished piece. Consider the following while brainstorming:

-

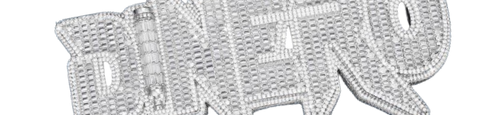

Purpose: What do you want your pendant to represent? It could be a personal symbol, a significant date, a loved one's initials, or even a favorite quote. Pinpointing the purpose will help guide the design.

-

Sketch: Start with a rough sketch of your ideas. Even if you're not an artist, sketching can help solidify your vision.

-

Inspiration: Look for inspiration everywhere — jewelry websites, nature, art, books, and even personal photos can be sources of design ideas.

-

Feedback: Share your designs with friends, family, or a jewelry consultant. They might provide insights or suggestions that can refine your concept.

-

Finalize the Design: With feedback in hand, refine your design until you're satisfied with how it looks and feels. Remember, this is your piece, so it should resonate deeply with you.

2. Make a CAD Computer Design of Your Design

Once you have a clear vision of your pendant, the next step is to translate that into a 3D computer-aided design (CAD). This digital representation will provide a clear and precise model of what the finished pendant will look like and is essential for the manufacturing process.

Outsource the Design

If you're not well-versed in 3D design or simply want a professional touch, consider outsourcing this step. The team at Icecartel is seasoned in translating pendant designs into detailed CAD models, ensuring accuracy and top-notch aesthetics. To collaborate with them, shoot an email to custom@icecartel.com or slide into their Instagram DMs @icecartel.

Try it Yourself

For the DIY enthusiasts, designing the pendant CAD model can be a rewarding endeavor. Popular software like Blender and AutoCAD offer comprehensive tools for 3D modeling.

Blender: This free, open-source software is user-friendly and perfect for beginners. Tons of tutorials are available online to help you get started.

AutoCAD: A bit more technical, AutoCAD is widely used in the jewelry design industry. For those unfamiliar with it, here's a handy video tutorial on AutoCAD 3D Modelling:

Whichever route you choose, remember that precision is key. The more accurate your CAD design, the more seamless the manufacturing process will be.

3. Find a Manufacturer

Upon finalizing your CAD design, the next step in bringing your pendant to life is finding the right manufacturer. This involves exporting your CAD design to an STL file, which stands for Stereolithography. This STL file is instrumental as it offers a 3D representation of your design, making it a universally accepted format in the world of jewelry manufacturing.

The significance of an STL file lies not just in its depiction of the pendant's geometry but also in its ability to:

-

Provide a Layer-by-layer breakdown: The file presents the design in a way that machines can understand, making it easier for 3D printing or milling processes.

-

Offer a Detailed Surface Representation: It ensures that the intricate details of your design are retained throughout the manufacturing process.

-

Ensure Compatibility: Being a widely accepted format, it's compatible with most manufacturing equipment, ensuring no design detail is lost.

If you're looking for trusted hands to transform your design into reality, Icecartel is a commendable choice. With years of expertise under their belt, they've mastered the art of immaculately turning designs into tangible, high-quality pendants.

However, the design file is just a part of what manufacturers need. Along with the STL file, be prepared to provide the following specifics to ensure your pendant turns out just the way you envisioned:

-

Dimensions: The overall size and proportions of your pendant.

-

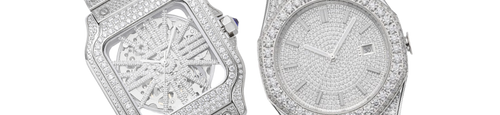

Base Metal: Specify the primary metal you want your pendant to be made from, such as gold, silver, or stainless steel.

-

Bail Type & Size: The part of the pendant where the chain goes through. Details regarding its design and dimensions are crucial.

-

Plating Metal: If you want a specific finish or color, like gold or rhodium plating, mention it.

-

Choice of Diamonds: Specify the type, size, and quality of diamonds or other gemstones you want to incorporate.

-

Adding Vermeil: If you want a thicker layer of gold plating over sterling silver, this is known as vermeil. Mention if you wish to have this added luxury.

Remember, communication is key. The more details and clarity you provide, the more accurate and tailored the final product will be.

The Manufacturing Process

The journey from a mere design on your computer to a tangible piece of jewelry involves a series of intricate steps, ensuring the final product is a perfect reflection of your vision. Let's delve into the key stages of this fascinating process:

-

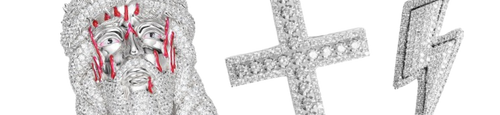

Creation of 3D Wax Model: Before any metal is involved, the manufacturing team takes your STL file and uses it to print a 3D wax model of your pendant. This wax replica serves a pivotal role as it acts as a mold. It is designed in such a way that, when metal is poured into it, the metal takes on the pendant's intended shape.

-

Set & Polish: Once the metal has cooled and solidified, the pendant is removed from the wax mold. The mold, having served its purpose, is typically melted away in a process called "lost wax casting". The newly formed pendant, although resembling your design, might have rough edges or a somewhat dull appearance. This is where setting and polishing come into play. Gemstones or diamonds are securely set into the pendant, followed by a thorough polishing to ensure a gleaming finish.

-

Plating, Enamelling, and Oxidation: Depending on your design specifications, the pendant might undergo additional finishing touches. Plating involves coating the pendant with a thin layer of metal (like gold or rhodium) to give it a particular color or luster. Enamelling is the process of fusing powdered glass to the pendant's surface for decorative purposes. Lastly, oxidation is a controlled process where the metal is intentionally tarnished to give the pendant an antique or contrasting finish.

-

Addition of Engravings (Optional): For those who desire an extra touch of personalization, engravings can be added at this stage. This could be anything from initials to intricate patterns, adding a unique signature to your custom pendant.

Throughout each step, precision and attention to detail are paramount, ensuring the final pendant is not only aesthetically pleasing but also of high quality and durability.

Frequently Asked Questions

How Much Does a Custom Pendant Cost?

The cost of a custom pendant varies widely based on several factors. The choice of base metal, the inclusion of gemstones or diamonds, the complexity of the design, and the labor involved all play a role in determining the price. Additionally, any additional features like plating, enameling, or engraving can also influence the cost. It's always best to consult directly with manufacturers or suppliers, like Icecartel, for a precise quote tailored to your design specifications.

How Much Cheaper is a Plated Pendant?

A plated pendant tends to be more cost-effective than one made from solid precious metals. Plating involves applying a thin layer of a precious metal (like gold) over a less expensive base metal, giving the appearance of the more valuable metal without the associated cost. Depending on the thickness and type of plating, as well as the base metal used, you could save anywhere from 20% to 60% compared to a pendant made entirely of the precious metal.

Do the Suppliers Offer Any Warranties?

Many reputable jewelry suppliers and manufacturers offer warranties on their products. Warranties typically cover manufacturing defects and might offer repairs or replacements within a specific timeframe. It's essential to inquire directly with your chosen supplier about the specifics of their warranty. Icecartel, for instance, is known for its commitment to quality and customer satisfaction, but always ensure to understand the terms of any warranty provided.

Last Words

Creating a custom pendant is a journey that marries creativity with craftsmanship. Each step, from conceptualization to completion, is vital in transforming an idea into a wearable piece of art. While the process may seem daunting, the end result—a pendant uniquely yours—is undeniably worth the effort. Whether you're commemorating a special moment, expressing personal style, or gifting a loved one, a custom pendant holds unmatched sentimental value. As you embark on this endeavor, always prioritize quality and work with trusted partners, ensuring your vision comes to life flawlessly.